ABOUT WELLDONE TECHNOLOGY

From Prototype to Production — Built on Quality.

Your trusted global partner, WELLDONE TECHNOLOGY delivers unmatched quality circuit boards, empowering innovation and driving technological progress.

WHO WE ARE

WELLDONE TECHNOLOGY is a globally recognized leader in circuit board manufacturing, backed by decades of proven expertise and a steadfast commitment to quality. Built on excellence. Trusted around the world.

WHAT WE DO

We specialize in custom PCB solutions—ranging from rapid prototyping to high-volume production—including advanced multi-layer, flex, and metal core boards, all backed by rigorous, comprehensive testing.

Our mission

Our mission is to empower innovation, deliver unmatched quality, and build enduring partnerships, setting industry standards while driving technological advancement ever forward globally and consistently

WELLDONE TECHNOLOGY, a subsidiary of Welldone Electronics, is a premier global manufacturer of Printed Circuit Boards (PCBs), offering end-to-end solutions ranging from single-sided prototypes to complex multi-layer FR4 and MCPCB designs. We support both prototype development and high-volume production across a wide array of industries, including medical devices, automotive, and consumer electronics such as televisions, DVDs, watches, gaming consoles, and home appliances.

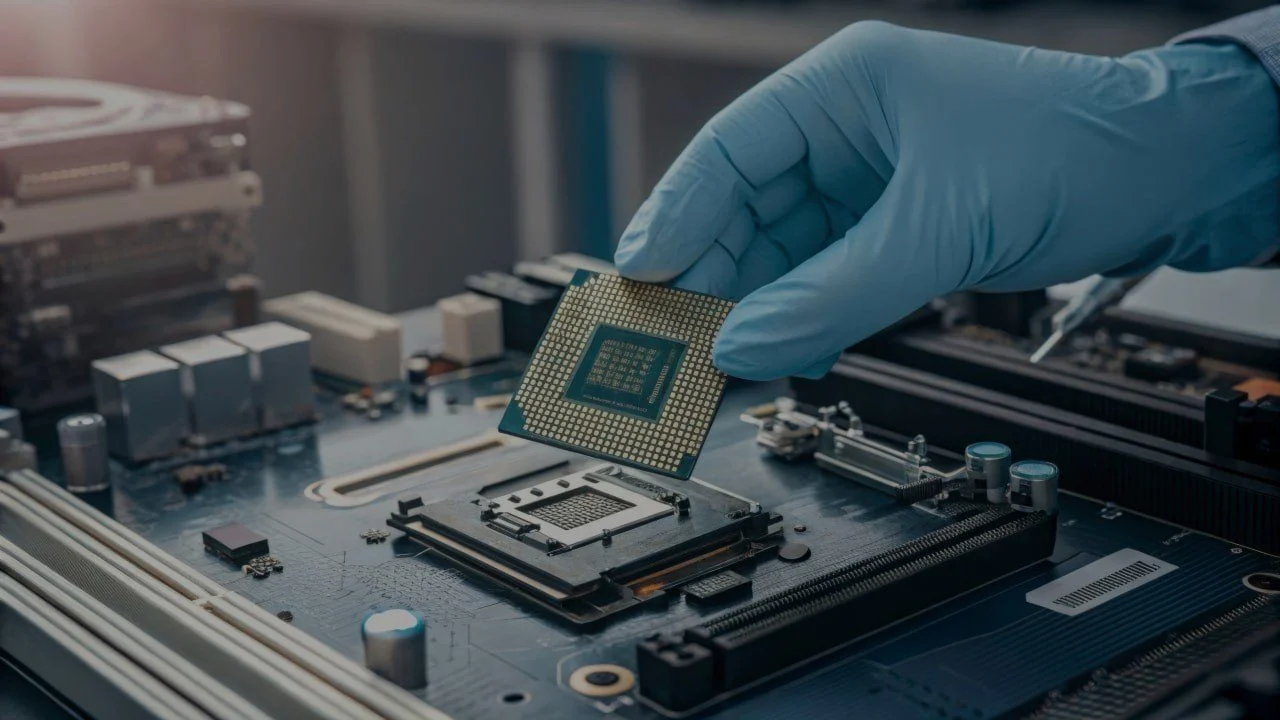

Driven by our mission to exceed customer expectations in quality, delivery, and cost-efficiency, we collaborate closely with design engineers and contract manufacturers to deliver tailored PCB solutions. Our advanced manufacturing facilities feature state-of-the-art equipment, including CNC drilling machines, copper deposition systems, automated tin plating and exposure lines, and fully automated imaging systems. We also offer a comprehensive selection of surface finishes, including Lead-Free HASL, Immersion Gold, OSP (Entek), Immersion Silver/Tin, and Gold Finger technology.

Since our inception, WELLDONE TECHNOLOGY has remained dedicated to continuous innovation and process improvement. We are committed to delivering precision, efficiency, and consistent quality—on time—while supporting the long-term success of our customers worldwide.

Local Support, Global Scale

Headquartered in California with world-class manufacturing in Shenzhen.

WHAT MAKES US DIFFERENT?

Certified Quality

IS09001, UL, and IPC Class 2 & 3 compliance.

Fast Lead Times

prototypes in as little as 5 days.

Full Range of Solutions

Rigid, Flex, Metal Core, HDI, and Rigid-Flex PCBs.

our products

-

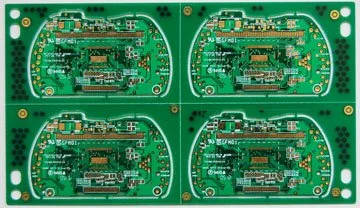

Rigid PCB (High TG)

2011-7-21 6:54:15

Rigid PCB (High TG) 14 layers FR4 High

-

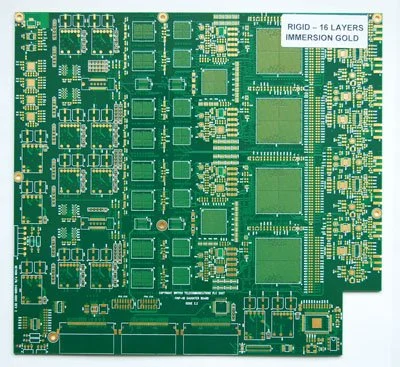

16 Layer Rigid PCB

2011-7-21 7:23:44

16 layers Rigid PCB FR4 Hoz ENIG

-

Rigid PCB (High TG)

2011-9-16 17:31:15

16 layers FR4 Hoz ENIG 0.040″

-

16 layer rigid PCB

2011-9-18 6:04:49

16 layers FR4 Hoz 0.100″ ENIG

WELLDONE TECHNOLOGY ecqipment

-

Drilling

-

Laminating

-

Laser drilling

-

aoi test

Our Manufacturing Process

-

Core Layer Preparation & Imaging

We begin with meticulous preparation and precise imaging of inner copper layers, ensuring flawless circuit patterns, reliable connection points for optimal performance, and reliability.

-

Multilayer Lamination & Drilling

We then proceed with expertly laminating multiple circuit layers together, ensuring robust inter-layer connections are precisely drilled for complex designs.

-

Outer Layer Circuitry & Plating

We continue by meticulously imaging, chemically etching, and precisely plating the outer copper layers, and reliable connection points for all components.

-

Protective Finishing & Routing

We then apply protective solder mask and specialized surface finishes, ensuring complete insulation and the precise routing of each board to its exact final dimensions.

Join our community to stay updated with the latest PCB innovations and cutting-edge manufacturing solutions.