OUR ADVANCED PCB MANUFACTURING CAPABILITIES

At WELLDONE TECHNOLOGY, our capabilities extend across the entire spectrum of printed circuit board manufacturing, from design optimization to rigorous testing and final delivery. We leverage cutting-edge technology, extensive expertise, and stringent quality control to deliver superior PCB solutions tailored to your most demanding requirements. Our commitment is to transform your innovative designs into high-performance, reliable hardware.

✅COMPREHENSIVE PCB TYPES & TECHNOLOGIES

✅ PRECISION MANUFACTURING PROCESSES

✅ UNCOMPROMISING QUALITY ASSURANCE & TESTING

✅ Expert Design & Engineering Support

CAPABILITIES For MCPCB

CAPABILITIES For FR4

WELLDONE TECHNOLOGY ecqipment

-

Drilling

-

Laminating

-

Laser drilling

-

aoi test

-

Cuper catting

-

brown oxide

-

etching

-

plant (wd pcb)

-

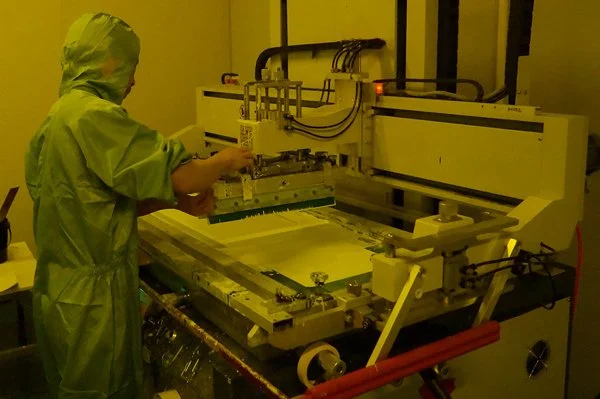

Silkscreen (WD PCB)

-

Exposing (WD pcb)

-

Drilling (Wd pcb)

-

Routing

OUR PROCESS

At WELLDONE TECHNOLOGY, our comprehensive manufacturing process meticulously includes Laminate Release, Laminate Shearing, Inner Layer Imaging, Etching, AOI Inspection, Lay-up, Lamination, Drilling, Copper Plating, Outer Layer Imaging, Etching, Solder Mask application, Surface Finishing, Routing, V-Cut, Electronic Testing, FQC, and precise Packaging.

READY TO START

BUILDING YOUR PCB?

Join our community to stay updated with the latest PCB innovations and cutting-edge manufacturing solutions.